I started out performing contract engineering work for ASU's Applied Nanobioscience Center (ANBC) in the winter of 2003. I performed electronic circuit design, mechanical design, and quite a bit of embedded micro-controller work.

Like most laboratories in the Biodesign Institute, the staff consisted primarily of chemists and biologists. Having an electronics engineer with mechanical design expertise around proved to be extremely valuable, and soon nearly every researcher had a project for me to tackle. After just a few months of contract work, the center director offered me a full-time position.

Rapid PCR Reactor and Chips

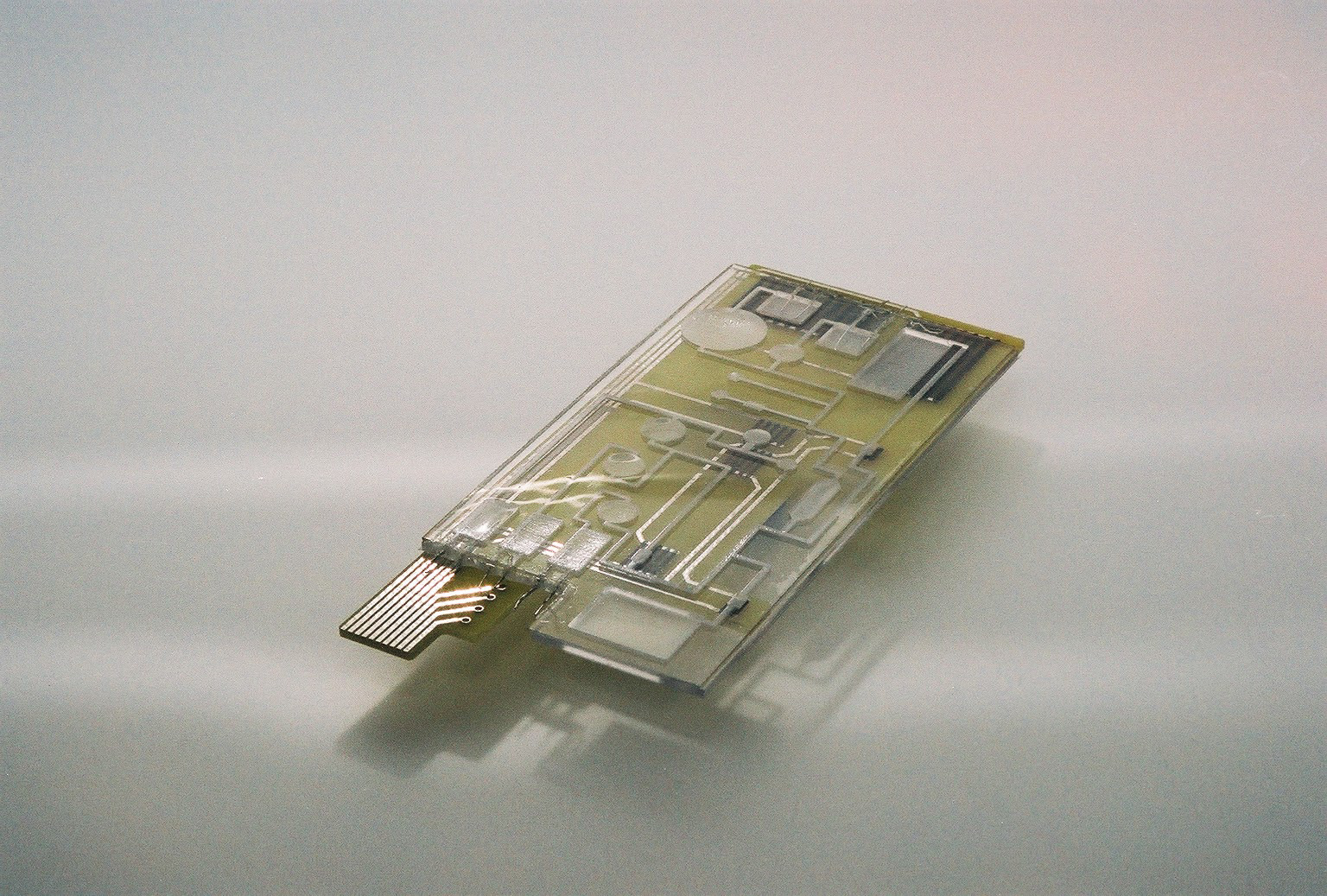

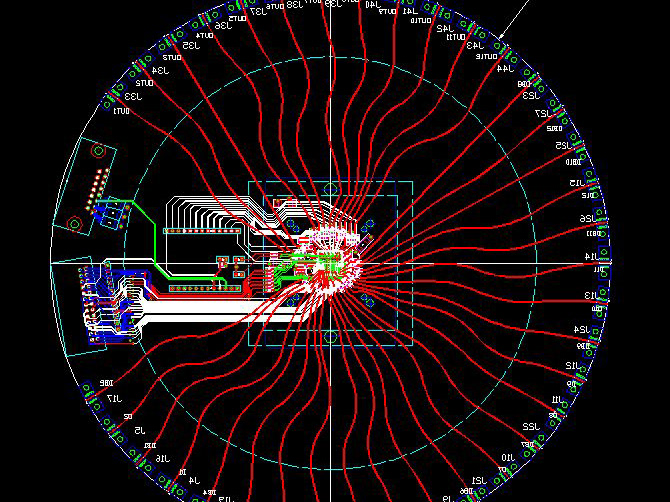

One of my first designs at ASU's Applied Nanobioscience Center was this

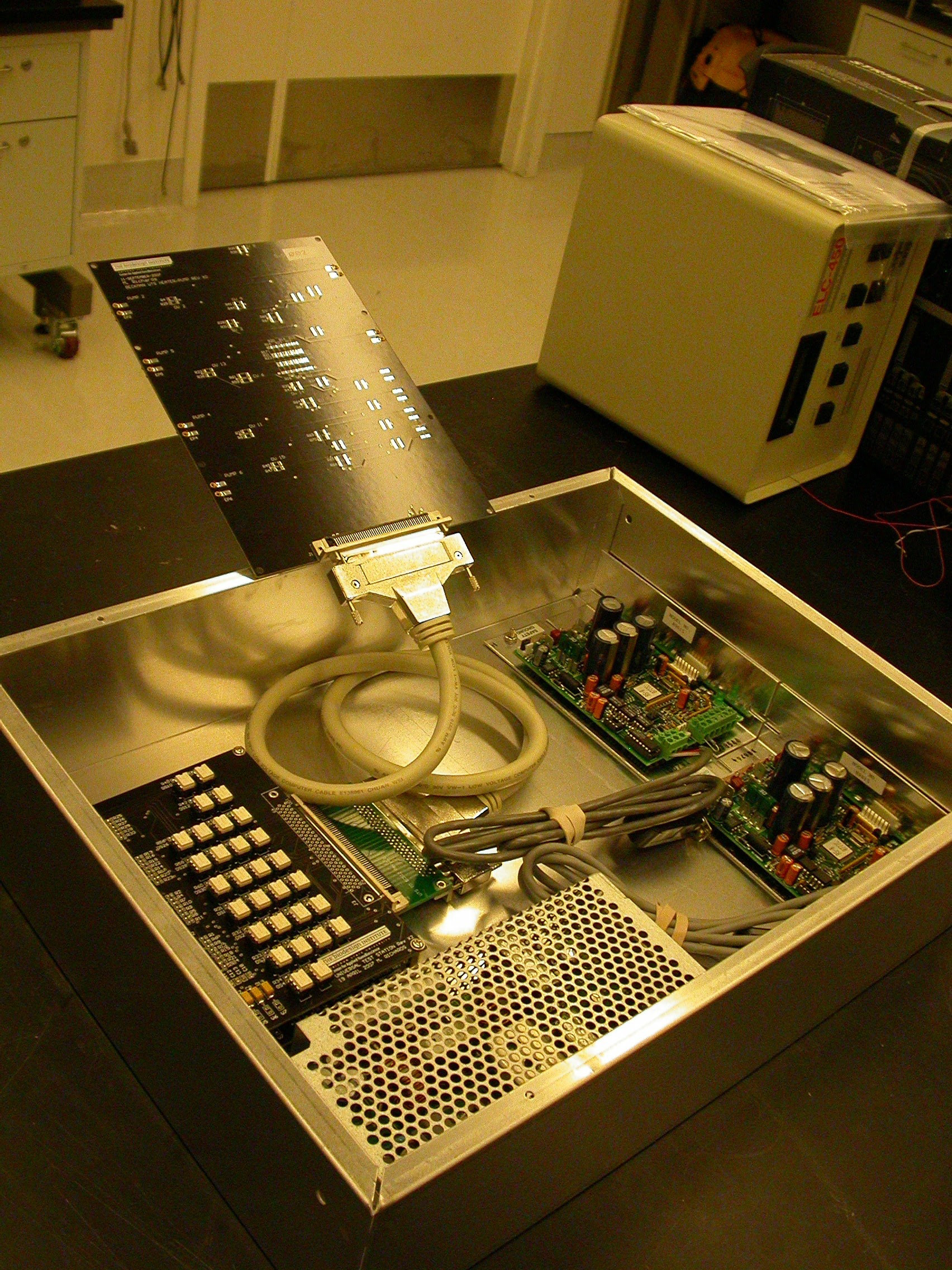

PCR reactor. The key to rapid Polymerase Chain Reaction is being able to change temperatures very quickly while maintaining precise thermal control. The PCR "Chips" (also my design) can be seen at the bottom of the photo.

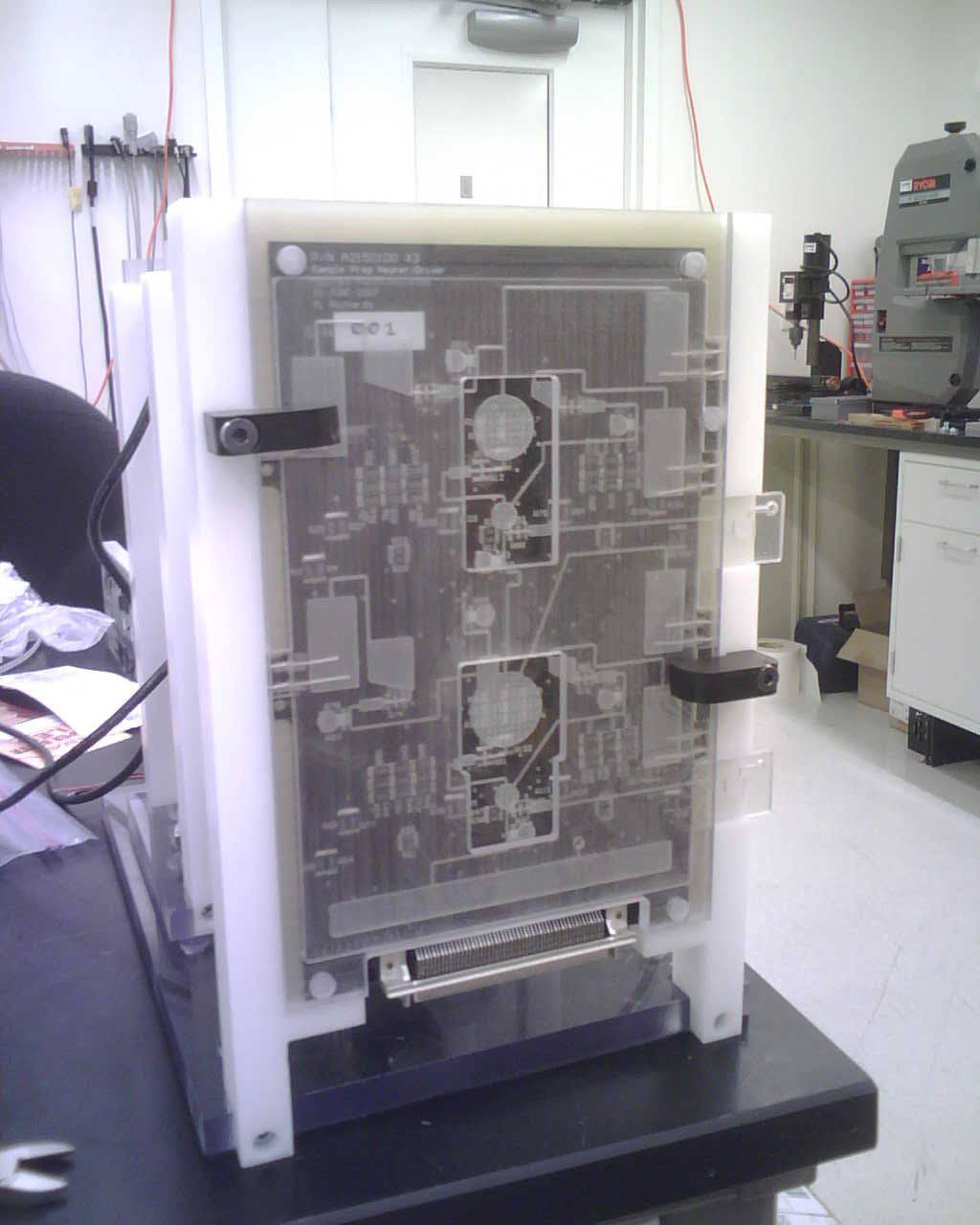

The chips were laser-cut and assembled from a sandwich of three layers, then solvent-welded together. The PCR reactor consists of two PID-controlled Peltier modules mounted in a custom heat-sink assembly.

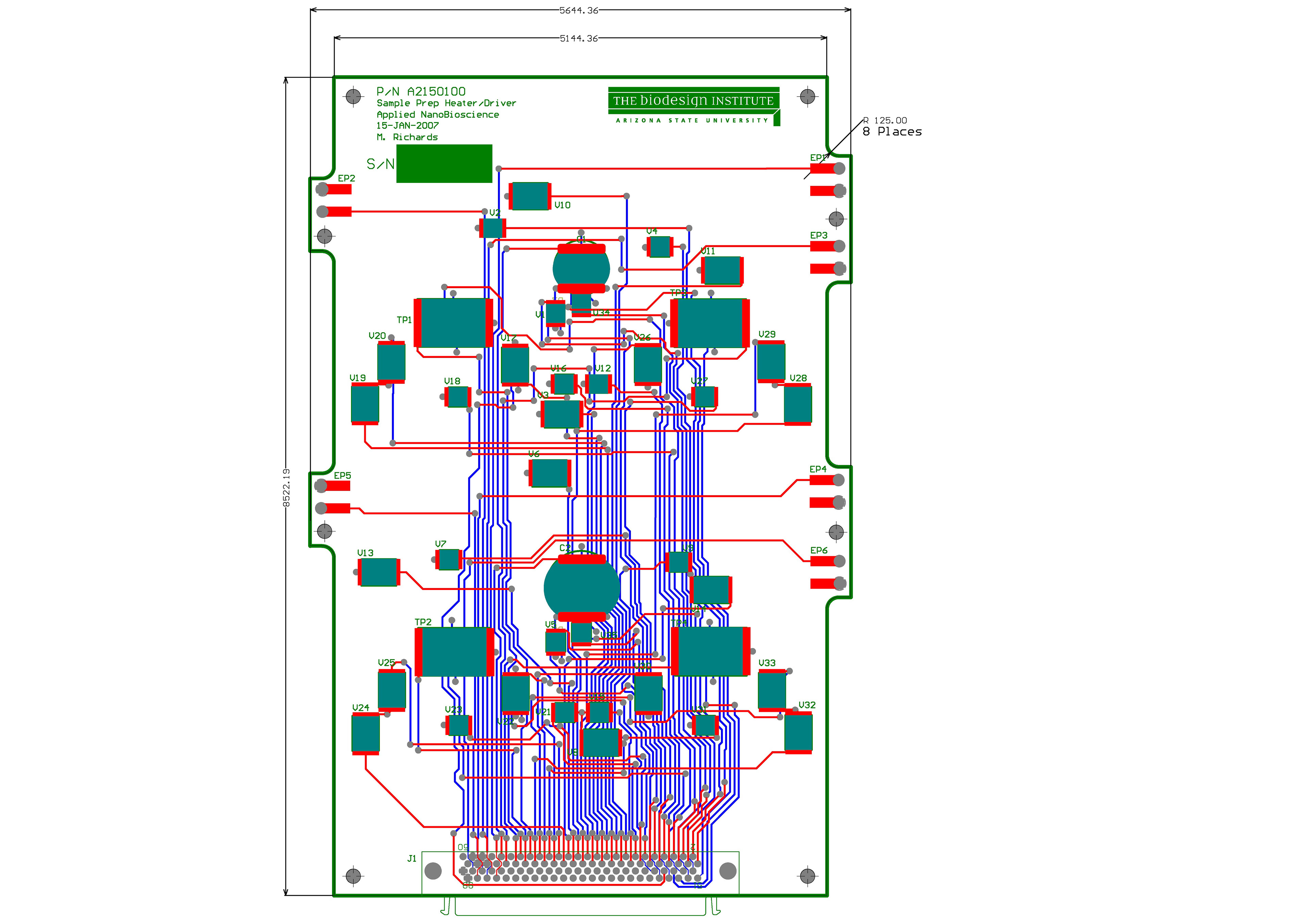

Subsequently, I designed and built several iterations of complete systems for conducting DNA sample preparation using self-contained microfluidic cartridges. These systems were commissioned by the FBI and, later, by British Forensic Science Services. The ultimate goal was a "sample to answer" system, combining our rapid PCR technology with Short Tandem Repeat (STR) typing.

The need for fast, portable DNA analysis required leveraging many different skills, including 2D and 3D mechanical design, 3D printing, micro-machining, laser cutting, analog and digital circuit design, embedded processor programming, as well as thermal and fluid simulations.